Quality Assurance

Quality refers to the sum of properties and characteristics that describe the product. A quality control system is an essential tool for all companies since it enables a company to provide dependable, and economical products of uniform quality. One of the most important objectives is that a quality control system, aims at preventing the defects rather than detecting the defects. There are several tools that companies use to enhance the quality in the production process. Perfecting the manufacturing processes rather than inspecting and repairing the flaw is the most efficient and economical method for establishing a standardized product quality.

Taking under consideration the specific needs of your product, process and equipment we are able to set-up a quality assurance protocole in order to monitor the quality of your product. We support the itermediate quality assurance steps so as to be able to monital at all timew the production process. In addition, testing the final product is also essential, especially if it holds some key operational chanarcteristics (i.e fire retardancy, superhydrophobic properties etc.)

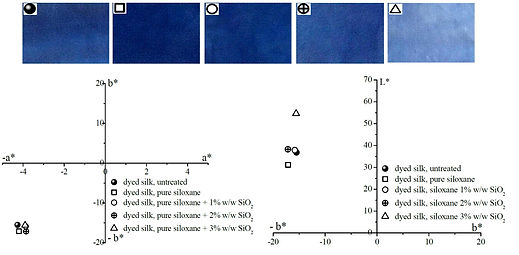

The evaluation of the final product can be performed with different techniques depending on the quality target set. Optical and Scanning Electron Microscopies, EDS Anaysis, ICP and XRD Analysis, Colorimetric analysis as well as thermal techniques such as DSc and TGA analysis can be used in order to evaluate the quality of a product.

We are familiar with ASTM procedures and other Standard Test Methods such as AATTC protocols. Depending on the nature of your product we are able to perform a variety of quality control testing.